To minimize electrical discharge hazards, use double-insulated tools and equipment, visually inspect all electrical equipment before use, and remove any equipment with damage or wear. Ground all exposed metal parts of equipment, and follow safety controls such as insulation, guarding, grounding, electrical protective devices, and safe work practices.

Homes, workplaces, and construction sites are common places where people encounter electrical hazards. It is crucial to prioritize electrical safety to prevent accidents and injuries. We will discuss 11 proven tips for minimizing electrical discharge hazards. Electricity is a powerful force that can cause severe harm if not handled properly.

By implementing these tips, individuals can significantly reduce the risks associated with electrical discharge hazards and create a safer environment for themselves and others. Read on to learn essential safety measures and best practices for managing and preventing electrical hazards.

Tip 1: Regularly Inspect Electrical Equipment

One of the most crucial steps in minimizing electrical discharge hazards is to regularly inspect all electrical equipment before use. By visually inspecting the equipment, you can identify any potential issues or damages that may pose a risk.

Visually Inspect All Electrical Equipment Before Use.

Before using any electrical equipment, it is essential to conduct a thorough visual inspection. This inspection involves carefully examining the equipment for any visible signs of damage, wear, or malfunction.

During the visual inspection, pay attention to the following:

- Look for any frayed cords or cables that may expose the underlying wires. These can be potential sources of electrical discharge.

- Check if the equipment’s grounding prongs are intact and not missing. Grounding is crucial in providing a safe path for electrical current to flow in case of a fault.

- Inspect the equipment for any cracks, dents, or other physical damages that may compromise its structural integrity.

Remove From Service Any Equipment With Frayed Cords, Missing Ground Prongs, Cracks, Or Other Damages.

If you come across any electrical equipment during the inspection that shows signs of damage such as frayed cords, missing ground prongs, cracks, or other damages, it is crucial to remove it from service immediately.

Continued use of damaged equipment can increase the risk of electrical discharge, leading to potential accidents or injuries. By taking prompt action and removing the equipment from service, you effectively eliminate the hazards associated with it.

Remember, regular inspections and prompt removal of damaged equipment ensure a safer working environment and reduce the likelihood of electrical discharge incidents.

Tip 2: Use Double-insulated Tools And Equipment

When it comes to minimizing electrical discharge hazards, one of the most effective tips is to use double-insulated tools and equipment. This is an essential safety measure that can significantly reduce the risk of electrical accidents, especially in high-risk areas.

Use Tools And Equipment That Are Double-insulated

Double-insulated tools and equipment are designed with an extra layer of insulation, providing an added level of protection against electrical shock. This insulation acts as a barrier between the electrical current and the user, effectively reducing the chance of any electrical discharge occurring.

Double-insulated tools and equipment are often the preferred choice in industries where there is a greater risk of electrical hazards, such as construction, manufacturing, and maintenance. These tools are specifically engineered to meet safety standards and regulations, ensuring the utmost protection for workers.

Look For Distinct Markings To Identify Double-insulated Products

Identifying double-insulated tools and equipment is crucial to ensure their proper use. Look for distinct markings or symbols on the tools and equipment that indicate they are double-insulated.

When purchasing new tools or equipment, always check for the presence of any labels or symbols that signify double insulation. These markings are typically provided by the manufacturer to guarantee compliance with safety standards and regulations.

Some commonly used symbols to identify double-insulated products include a square within a square, two parallel rectangles, or the letters “DI” enclosed in a circle. Familiarize yourself with these markings to ensure you are using the correct tools and equipment for the task at hand.

In conclusion, using double-insulated tools and equipment is a proven strategy for minimizing electrical discharge hazards. By adhering to this tip, you can significantly reduce the risk of electrical accidents and create a safer work environment. Always prioritize safety by investing in the right tools and equipment that offer double insulation and ensure they are properly marked and identified.

Tip 3: Ground Exposed Metal Parts Of Equipment

To minimize electrical discharge hazards, one proven tip is to ground all exposed metal parts of equipment. This can be achieved by visually inspecting all electrical equipment before use and removing any with damaged cords or missing ground prongs.

When it comes to minimizing electrical discharge hazards, one crucial step is to ensure that all exposed metal parts of equipment are properly grounded. This reduces the risk of electrical discharge hazards and helps to create a safer environment for everyone. Grounding is the process of connecting the metal parts of electrical equipment to the ground or earth, creating a direct path for electrical currents to flow in case of faults or surges. By grounding exposed metal parts, you create a low resistance pathway for electricity to follow, preventing the buildup of static charges and reducing the chances of electrical shocks or sparks.Ensure All Exposed Metal Parts Of Equipment Are Properly Grounded

Properly grounding exposed metal parts of equipment is essential for electrical safety. This practice helps to mitigate the risk of electrical discharge hazards and ensures the smooth flow of electrical currents within the system. To achieve this, follow these guidelines:- Inspect and verify that all equipment and appliances have three-pronged plugs with the third prong (the grounding prong).

- Check for any loose or damaged grounding wires and repair or replace them immediately.

- Install and maintain grounding systems, such as grounding rods or grounding wires, if required.

- Use grounding mats or conductive flooring in areas where sensitive equipment is located to dissipate static charges effectively.

- Regularly test the effectiveness of grounding by using a ground resistance tester or multimeter.

Tip 4: Install And Test Residual Current Devices (rcds)

Install and test residual current devices (RCDs) to minimize electrical discharge hazards in your home. RCDs can detect and quickly shut off the electrical power to prevent electric shock incidents, making them an essential safety measure.

When it comes to minimizing electrical discharge hazards, one of the most effective measures you can take is to install and regularly test residual current devices (RCDs). These devices play a crucial role in detecting and preventing electrical hazards, offering an added layer of protection for both residential and commercial spaces.

Check That Residual Current Devices (rcds) Are Installed And Regularly Tested

Before we dive into the importance of RCDs, it’s essential to ensure that you have these devices installed in your electrical system. Check your circuit breaker panel or consumer unit to confirm the presence of RCDs. If you’re unsure about their installation, it’s always best to consult with a qualified electrician.

RCDs help detect faults in the electrical circuit and automatically cut off the power supply, preventing severe electrical accidents like electric shocks and fires. These devices monitor the flow of electrical current, detecting any imbalances between the live and neutral wires. If an imbalance is detected, such as when a portion of current flows through an unintended path like a person’s body, the RCD quickly shuts off the power, minimizing the risk of injury or damage.

Proper installation and regular testing of RCDs are crucial to ensure their effectiveness. It’s recommended to have a qualified electrician conduct periodic tests to verify that the RCDs are functioning correctly. Regular testing ensures that the devices are responsive and capable of promptly disconnecting the power supply when needed.

Rcds Help Detect And Prevent Electrical Hazards

By installing and routinely testing RCDs, you are taking a proactive step towards creating a safer electrical environment. These devices provide significant benefits, including:

- Protection against electric shock: RCDs detect even the slightest imbalance in electrical current, immediately disconnecting the power source. This rapid response greatly reduces the risk of electric shock, particularly in situations where a person comes into contact with a faulty electrical appliance or wiring.

- Minimization of fire hazards: Faulty electrical circuits and appliances can lead to arcing or electrical sparks, which can quickly escalate into fires. RCDs can swiftly identify these faults and interrupt the circuit, preventing the potential for fire outbreaks.

- Enhanced electrical safety: Whether you own a residential property, an office space, or a commercial establishment, prioritizing electrical safety is vital. RCDs play a critical role in maintaining the safety of individuals and property by swiftly detecting and mitigating electrical hazards.

Remember, installing and regularly testing RCDs is an important step in minimizing electrical discharge hazards. Make sure to consult with a qualified electrician for proper installation and periodic testing to ensure maximum effectiveness. Your safety and the safety of those around you depend on it.

Tip 5: Perform Planned Preventative Maintenance And Inspections

Performing planned preventative maintenance and inspections is a crucial tip for minimizing electrical discharge hazards. By regularly checking and maintaining electrical equipment, you can reduce the risk of electric sparking or other potential hazards.

Regular planned preventative maintenance and visual inspections play a crucial role in minimizing electrical discharge hazards. By confirming and adhering to a scheduled maintenance plan, you can easily identify and address potential electrical hazards before they escalate into dangerous situations. These inspections not only ensure the safety of your electrical systems but also promote a secure living environment for you and your loved ones.Confirm Regular Planned Preventative Maintenance

One effective way to proactively manage electrical discharge hazards is by implementing regular planned preventative maintenance. This involves scheduling routine inspections and maintenance activities for all electrical equipment and systems in your home. By doing so, you can identify any faulty or malfunctioning components before they lead to electrical discharge incidents. To ensure your maintenance plan is effective, it is essential to engage qualified professionals who have in-depth knowledge and expertise in electrical systems. They can thoroughly inspect your electrical infrastructure, identify potential hazards, and take necessary preventive measures to mitigate risks. Regular maintenance takes into account factors like wear and tear, age, and environmental elements that could impact the performance and safety of your electrical equipment.Visual Inspections: Identifying And Addressing Hazards

In addition to planned preventative maintenance, visual inspections are a vital aspect of minimizing electrical discharge hazards. These inspections involve visually examining electrical equipment, wiring, outlets, and other components for any signs of damage, wear, or potential hazards. During visual inspections, it is crucial to look for signs such as frayed wires, loose connections, exposed conductors, or signs of overheating. Any deterioration or abnormalities should be addressed promptly to prevent electrical discharge incidents. Remember, visual inspections are an opportunity to catch minor issues early on and prevent them from turning into major safety concerns. To assist you in performing effective visual inspections, consider creating a checklist that includes the specific areas and items to inspect. This checklist can serve as a guide during your inspections, ensuring that no potential hazards are overlooked. Regular visual inspections help maintain the integrity of your electrical systems, ensuring they are functioning safely and reducing the risk of electrical discharge hazards. In conclusion, performing regular planned preventative maintenance and visual inspections is an essential step in minimizing electrical discharge hazards. It allows you to identify and address potential risks before they pose a threat to your safety. By adhering to a scheduled maintenance plan and inspecting your electrical equipment visually, you can create a secure living environment for yourself and your family. Remember, prevention is key when it comes to electrical safety. References: – [PDF] Electrical Safety. (n.d.). Retrieved from https://www.nfpa.org/-/media/Files/News-and-Research/Resources/Electrical/Pursuing-Digital-Discipline.ashx – Controlling electrical hazards (as well as other hazards) reduces the risk. (n.d.). Retrieved from https://www.osha.gov/Publications/osha3930.pdfTip 6: Provide Training On Electrical Hazard Identification And Prevention

Tip 6: To minimize electrical discharge hazards, it is important to provide training on electrical hazard identification and prevention. By educating individuals on how to identify potential electrical hazards and take necessary precautions, the risk of electrical accidents can be significantly reduced.

Conduct Training Sessions To Educate Individuals On Identifying And Preventing Electrical Hazards.

One of the most effective ways to minimize electrical discharge hazards is to provide thorough training on electrical hazard identification and prevention. By educating individuals on the potential dangers and appropriate safety measures related to electricity, you can empower them to make informed decisions and take necessary precautions. Training sessions should cover a range of topics, such as recognizing common electrical hazards, understanding electrical safety devices, and implementing best practices for safe electrical work.

Ensure Everyone Has The Necessary Knowledge And Skills To Stay Safe.

All individuals in your organization should have the necessary knowledge and skills to identify and mitigate electrical hazards. This includes employees, contractors, and other relevant stakeholders. By ensuring everyone is properly trained, you can create a culture of safety where electrical hazards are recognized and addressed promptly. This also helps to foster a sense of responsibility and accountability among individuals, as they understand the importance of their role in minimizing the risks associated with electrical discharge.

Tip 7: Follow Arc Flash Safety Guidelines

Follow these 11 proven tips to minimize electrical discharge hazards, including tip #7: Follow Arc Flash Safety Guidelines. By adhering to proper safety guidelines, such as using double-insulated tools and visually inspecting all electrical equipment, you can greatly reduce the risk of electrical hazards.

Stay safe and protected by following these tips.

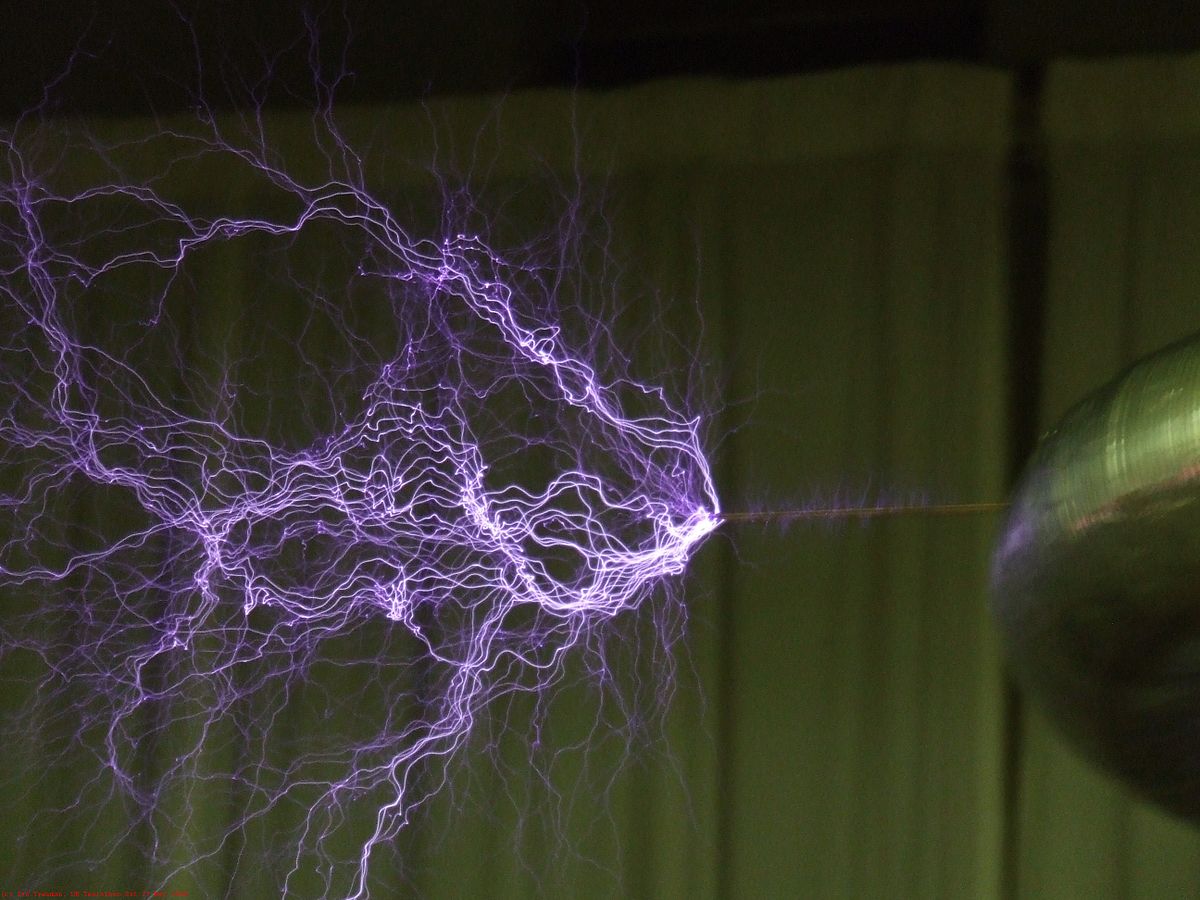

Adhere to arc flash safety guidelines to prevent luminous electrical discharge. This includes following proper procedures and using protective gear.

In order to minimize the risks associated with electrical discharge hazards, it is crucial to follow arc flash safety guidelines. Arc flash refers to the luminous electrical discharge that occurs through the air, often characterized by bright electrical sparking. By adhering to proper procedures and utilizing the necessary protective gear, you can greatly reduce the likelihood of arc flash accidents and the resulting injuries. Here are some key tips to help you navigate arc flash safety guidelines.

Follow Proper Procedures

When it comes to arc flash safety, it is essential to follow the correct procedures to ensure optimal protection. Proper procedures typically involve wearing the appropriate personal protective equipment (PPE), including flame-resistant clothing, safety glasses, and insulated gloves. It is important to carefully review and understand the arc flash risk assessment and the arc flash boundary before attempting any work near live electrical systems. Remember to adhere to lockout/tagout procedures and work permits, as they help prevent accidental energization of equipment and minimize the risk of arc flash incidents.

| Proper Procedure Checklist |

|---|

| Wear appropriate PPE, including flame-resistant clothing, safety glasses, and insulated gloves. |

| Familiarize yourself with the arc flash risk assessment and the arc flash boundary. |

| Adhere to lockout/tagout procedures to prevent accidental energization of equipment. |

| Obtain work permits as required. |

Utilize Protective Gear

Protective gear plays a critical role in minimizing the risks associated with arc flash incidents. To provide effective protection, ensure that all PPE is in good condition and properly fitted. Flame-resistant clothing should cover the entire body, including arms, legs, and torso, while safety glasses should provide sufficient eye protection. Insulated gloves should be used when working directly with live electrical systems to prevent electrical shocks and burns. By using the appropriate protective gear, you can significantly reduce the potential harm caused by arc flash incidents.

- Ensure all PPE is in good condition and properly fitted.

- Wear flame-resistant clothing that covers the entire body.

- Use safety glasses that provide sufficient eye protection.

- Utilize insulated gloves when working with live electrical systems.

By adhering to arc flash safety guidelines and following proper procedures, you can effectively minimize the risks associated with luminous electrical discharge. Remember to wear the appropriate protective gear and never underestimate the importance of practicing electrical safety in every task you undertake.

Tip 8: Follow Electrical Safety Protocols In Construction

Follow Electrical Safety Protocols in Construction to minimize electrical discharge hazards. Use double-insulated tools, visually inspect all equipment, and ground exposed metal parts. Employ insulation, guarding, grounding, protective devices, and safe work practices to reduce electrical hazards.

Construction Workers Should Follow Specific Electrical Safety Protocols.

Construction sites pose unique electrical hazards that require specific safety protocols to be followed. Electricians, contractors, and other construction workers should be well-versed in these protocols to ensure their safety and minimize the risk of electrical discharge hazards. By adhering to these guidelines, they can create a safer work environment and prevent potentially life-threatening accidents.They Should Be Aware Of The Potential Dangers And Take Necessary Precautions.

Working with electricity in a construction setting can be extremely hazardous if proper precautions are not taken. Construction workers must be aware of the potential dangers and understand the importance of following electrical safety protocols. They should prioritize their safety by wearing appropriate personal protective equipment (PPE), such as insulated gloves and safety goggles, to minimize the risk of electrical shocks or burns. Additionally, they should be trained on how to identify and respond to electrical hazards, such as exposed wires or faulty equipment.By Following These Electrical Safety Protocols, Construction Workers Can Mitigate The Risks.

- Always de-energize electrical equipment and circuits before working on or near them. Use proper lockout/tagout procedures to prevent accidental energization.

- Inspect and maintain electrical tools and equipment regularly to identify any potential defects or malfunctions. Replace damaged or worn-out equipment promptly.

- Keep a safe distance from overhead power lines and ensure that any equipment or materials being used are kept away from them as well.

- Use ground fault circuit interrupters (GFCIs) to protect against electrical shock in areas prone to moisture or water exposure.

- Properly label and identify electrical panels, switches, and equipment to ensure easy identification and proper usage.

- Implement a clear communication system and establish an emergency plan to address electrical hazards promptly.

- Train all workers on electrical safety practices and procedures, including how to respond to electrical accidents and emergencies.

- Ensure that only qualified and trained personnel handle electrical installations, repairs, or modifications.

- Provide adequate lighting in work areas to minimize the risk of accidental contact with live electrical components.

- Keep work areas clean and free of debris to prevent tripping hazards that could lead to accidental contact with electrical equipment.

- Regularly assess the work environment for potential electrical hazards and implement necessary control measures to minimize risks.

Tip 9: Use Antistatic, Electrostatic, Or Insulating Ppe

When it comes to electrical discharge hazards, using the right personal protective equipment (PPE) is crucial. Tip 9 emphasizes the importance of applying antistatic, electrostatic, or insulating PPE to ensure an extra layer of protection against electrical discharge hazards.

Apply Antistatic, Electrostatic, Or Insulating Personal Protective Equipment (ppe)

Antistatic, electrostatic, or insulating PPE plays a vital role in minimizing electrical discharge hazards. By using appropriate PPE, you can protect yourself and your team members from potential electrical accidents. Here are some key points to consider:

- Choose the right type of PPE based on the specific electrical hazard you are dealing with. Antistatic PPE is designed to prevent the build-up of static electricity, while electrostatic PPE is effective in dissipating static charges. Insulating PPE, on the other hand, is designed to provide a barrier against electrical currents.

- Ensure that your PPE meets the necessary safety standards and certifications to guarantee its effectiveness.

- Inspect your PPE regularly to identify any signs of wear and tear. Replace damaged or worn-out PPE to maintain its effectiveness.

- Train yourself and your team members on the proper use and maintenance of PPE. This includes understanding how to properly wear and adjust the equipment for maximum protection.

- Depending on the nature of your work, you may need to use a combination of different types of PPE to ensure comprehensive protection.

By following these guidelines, you can significantly reduce the risk of electrical discharge hazards and promote a safer working environment.

Credit: en.wikipedia.org

Tip 10: Minimize Electrical Resistance

To minimize electrical discharge hazards, one proven tip is to minimize electrical resistance. This can be achieved through insulation, grounding, and using double-insulated tools and equipment, among other safety measures.

Reduce Electrical Resistance By Ensuring Proper Connections And Efficient Electrical Systems

One of the most effective ways to minimize electrical discharge hazards is by reducing electrical resistance. When electrical systems have higher resistance, it can lead to the buildup of excess heat and increase the risk of electrical discharge. To mitigate this risk, it is crucial to ensure proper connections and efficient electrical systems. Here are some tips to help you achieve this:

- Inspect and tighten connections: Loose connections can contribute to increased resistance, so it is vital to regularly inspect and tighten all electrical connections. This includes connections in circuit breakers, outlets, switches, and electrical panels.

- Use high-quality materials: Using high-quality wiring, connectors, and terminals can help minimize electrical resistance. Invest in materials that are designed for your specific electrical system requirements and ensure they are suitable for the applicable voltage and current levels.

- Properly ground electrical equipment: Grounding electrical equipment helps divert unwanted electrical currents and reduce the risk of electrical discharge. Ensure that all electrical equipment is properly grounded and that grounding connections are regularly inspected for integrity.

- Maintain clean and corrosion-free connections: Dirt, dust, and corrosion can increase electrical resistance. Regularly clean and inspect connections to remove any debris or corrosion. Consider using anti-corrosion sprays or compounds to protect connections in corrosive environments.

- Optimize wire size and gauge: Using the correct wire size and gauge for your electrical system can help minimize resistance. Consult electrical codes and regulations or consult with a licensed electrician to ensure you are using the appropriate wire size for your specific application.

- Ensure proper wire routing: Proper wire routing can prevent unnecessary bends, kinks, or sharp turns, which can increase resistance. Avoid running wires near heat sources or sharp edges that could damage the insulation.

- Maintain proper insulation: Insulation plays a crucial role in preventing electrical discharge. Inspect all wires and cables for signs of damage or wear and promptly replace any damaged insulation to maintain electrical safety.

- Regularly inspect and maintain electrical systems: Conduct regular inspections and maintenance of your entire electrical system. This includes checking for loose wires, damaged insulation, or any other potential issues that could contribute to increased resistance.

- Consider using surge protection devices: Surge protection devices can help prevent electrical discharge caused by voltage spikes. Install surge protection devices throughout your electrical system, including at the main electrical panel and sensitive equipment outlets.

- Train employees on electrical safety: Educate employees about the importance of minimizing electrical resistance and the potential hazards associated with electrical discharge. Provide proper training on safe electrical practices, including how to identify and address issues related to resistance.

By implementing these tips and minimizing electrical resistance in your electrical systems, you can significantly reduce the risk of electrical discharge hazards. Remember, always consult with qualified professionals or electricians for specific guidance related to your electrical system.

Tip 11: Follow A Home Electrical Safety Checklist

Minimize electrical discharge hazards by following a home electrical safety checklist. Use double-insulated tools, visually inspect equipment, and ground all exposed metal parts. Remove any equipment with frayed cords or missing ground prongs to prevent electrical hazards.

Ensuring electrical safety at home is of utmost importance to protect yourself, your family, and your property. One effective way to minimize electrical discharge hazards is to follow a home electrical safety checklist. This checklist covers various aspects of electrical safety and serves as a guide to ensure that all necessary safety measures are in place.

Refer To A Home Electrical Safety Checklist To Ensure All Safety Measures Are In Place

A home electrical safety checklist is a comprehensive tool that can help you assess and address potential electrical hazards within your living space. It serves as a reminder to perform regular checks and preventive maintenance to ensure the safety of your electrical system. Here are some key areas typically covered in a home electrical safety checklist:

1. Visual Inspection: Regularly inspect all electrical equipment for any signs of damage or wear. Look for frayed cords, loose connections, cracked tool casings, or missing ground prongs. If you notice any issues, remove the equipment from service until it is properly repaired or replaced.

2. Grounding: Ground all exposed metal parts of equipment to prevent electrical shocks. Verify that all outlets, switches, and appliances have three-pronged plugs and that they are properly grounded.

3. Overloading: Be mindful of not overloading electrical circuits. Avoid using multiple high-wattage appliances on the same circuit simultaneously. Distribute the load evenly or consider installing additional circuits if necessary.

4. Outlet Safety: Check all outlets and switches for any signs of damage, such as cracks or loose connections. Ensure that all outlet covers are in place and secure.

5. Extension Cords: Avoid using extension cords as permanent solutions. If you do use extension cords, make sure they are in good condition and not overloaded. It’s recommended to opt for a proper electrical installation instead.

6. Outdoor Electrical Safety: Pay special attention to outdoor electrical components. Regularly inspect and maintain exterior lighting, outlets, and electrical panels to protect them from the elements.

7. Childproofing: Keep electrical outlets out of children’s reach by using outlet covers or childproofing devices.

8. Regular Maintenance: Create a schedule for regular maintenance tasks such as cleaning and inspecting electrical components. This includes cleaning dust from vents, replacing filters, and checking connections.

9. Fire Safety: Have a fire extinguisher readily accessible and ensure that smoke detectors are installed and functioning properly throughout your home.

10. Education and Preparedness: Educate yourself and your family members about electrical safety practices and emergency procedures. Make sure everyone knows the location of the main electrical panel, how to shut off power in an emergency, and what to do in the event of an electrical accident.

11. Professional Inspection: Consider hiring a licensed electrician to conduct a thorough inspection of your home’s electrical system. They can identify any potential hazards or code violations and provide expert recommendations for improvement.

By following a home electrical safety checklist, you can minimize the risk of electrical discharge hazards and create a safer living environment for you and your loved ones. Don’t underestimate the importance of electrical safety, as implementing these measures can help prevent accidents and property damage caused by electrical incidents.

Frequently Asked Questions For 11 Proven Tips For Minimizing Electrical Discharge Hazards

What Are 10 Safety Rules In Electrical?

To ensure electrical safety, follow these 10 guidelines: 1. Use double-insulated tools and equipment, and inspect them before use. 2. Keep all electrical equipment dry and away from water sources. 3. Regularly check for frayed cords, missing ground prongs, or damaged tool casings.

4. Use residual current devices and test them regularly. 5. Ground all exposed metal parts of equipment. 6. Insulate electrically energized wires and parts. 7. Follow safe work practices and use proper personal protective equipment. 8. Remove any equipment with electrical sparking or bright discharge.

9. Train employees on identifying and preventing electrical hazards. 10. Follow the hierarchy of controls: elimination, substitution, engineering controls, administrative controls, and personal protective equipment.

How Can Electrical Hazards Be Minimized?

To minimize electrical hazards, follow these steps: use double-insulated tools and equipment, visually inspect all electrical equipment before use, remove any damaged equipment, ground all exposed metal parts, and mark distinctively. Also, employ insulation, guarding, grounding, protective devices, and safe work practices.

Remember, prevention is key to electrical safety.

What Are The Five Main Types Of Controls For Electrical Hazards?

The five main types of controls for electrical hazards are elimination, substitution, engineering controls, administrative controls, and personal protective equipment (PPE). These controls help to physically remove or replace the hazard, isolate people from the hazard, change work practices, and protect workers with appropriate equipment.

What Safeguards Can You Use To Help Reduce Electrical Hazards?

To help reduce electrical hazards, you can use safeguards such as insulation, guarding, grounding, electrical protective devices, and safe work practices. Insulation is a great way to protect individuals from electrically energized wires and parts. Additionally, make sure to visually inspect all electrical equipment before use and remove any damaged or faulty equipment from service.

Conclusion

To ensure the safety of your home and minimize electrical discharge hazards, it is crucial to follow these proven tips. Start by regularly checking and maintaining residual current devices and conducting visual inspections. Use double-insulated tools and equipment, and ground all exposed metal parts.

Visually inspect all electrical equipment before use and remove any damaged equipment from service. Additionally, consider insulation, guarding, grounding, electrical protective devices, and safe work practices to safeguard against electrical hazards. By implementing these tips, you can greatly reduce the risk of electrical accidents and ensure the well-being of yourself and your loved ones.

Stay safe!